Makampani opanga magalimoto ndi ofanana ndi zatsopano, zomwe zimafuna kulondola kosalekeza, kuthamanga, komanso kudalirika pakupanga zinthu. Pakati pazigawo zofunika kwambiri zamagalimoto, makina otulutsa mpweya - makamaka mapaipi otulutsa mpweya - amagwira ntchito yofunika kwambiri pakuyendetsa galimoto, kuwongolera mpweya, komanso kuchepetsa phokoso. Pamene opanga amayesetsa kukwaniritsa miyezo yapamwamba komanso zomwe akufuna kupanga, maloboti owotcherera atuluka ngati zida zofunika kwambiri popanga makina otulutsa mpweya. Nkhaniyi ikuwunika momwe makina owotcherera a robotic, ophatikizidwa ndi zida zapamwamba zoyikira ngatima rotary tilt positionersndimakonda makonda, akusintha kamangidwe ka mapaipi otulutsa utsi wamagalimoto, kukweza mphamvu, kusasinthasintha, ndi mtundu wazinthu zomwe sizinachitikepo.

1. Kuvuta kwa Kupanga Mapaipi a Exhaust

Mapaipi otulutsa utsi amakumana ndi zovuta kwambiri, kuphatikiza kutentha kwambiri, mpweya wowononga, komanso kugwedezeka kwa makina. Kuti apirire zovutazi, nthawi zambiri amapangidwa kuchokera ku chitsulo chosapanga dzimbiri kapena chitsulo cholumikizika ndipo amafuna ma weld opanda msoko, opanda mpweya kudutsa ma geometries ovuta. Njira zowotcherera pamanja nthawi zambiri zimavutikira kuti zisungidwe mosasinthasintha pazogwiritsa ntchito zotere, zomwe zimatsogolera ku zolakwika monga porosity, kusakanizika kosakwanira, kapena kupotoza.

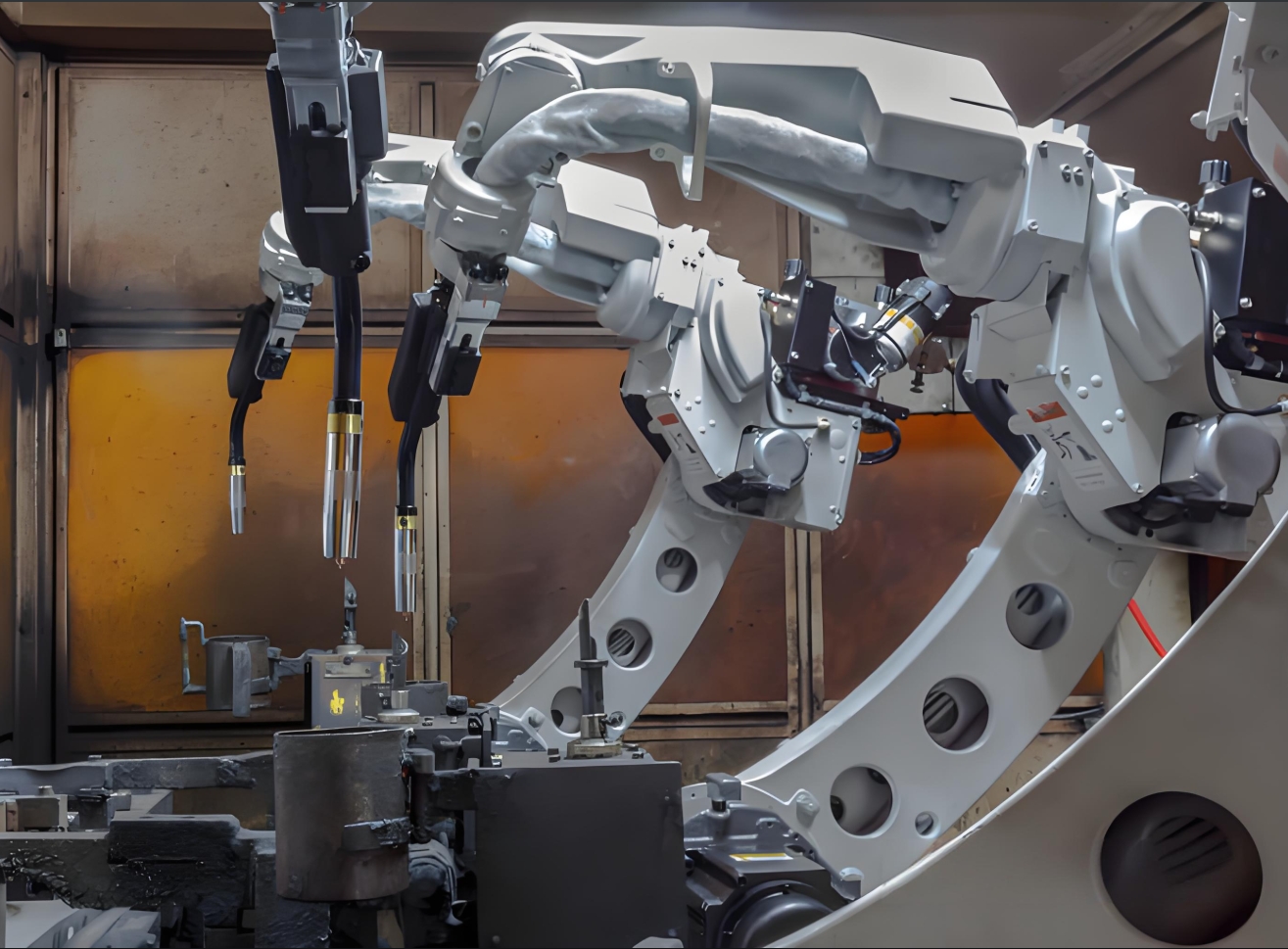

Maloboti owotcherera, komabe, amapambana pakuwongolera zovuta izi. Zokhala ndi mafotokozedwe amitundu yambiri komanso zolumikizidwa ndi makina oyika bwino, amatulutsa ma weld opanda cholakwika pamalo opindika, ma flanges, ndi olowa -ofunikira kuwonetsetsa kuti dongosolo lotulutsa likuyenda bwino.

2. Kuwotcherera kwa Robotic mu Ntchito: Mapulogalamu Ofunika Kwambiri a Mapaipi a Exhaust

2.1 Tube-to-Flange ndi Tube-to-Muffler Welding

Makina otulutsa mpweya amakhala ndi zinthu zingapo, kuphatikiza mapaipi, osinthira othandizira, ma resonator, ndi ma mufflers. Makina owotchera ma robotiki amapangitsa kulumikizana kwa machubu kupita ku ma flanges kapena ma muffler housings, kuwonetsetsa kulowa kwa yunifolomu ndikuchepetsa madera omwe amakhudzidwa ndi kutentha (HAZ). Mwachitsanzo, a6-axis articulated robotimatha kuyenda mozungulira chizungulire cha chitoliro, kukhala ndi ngodya zabwino kwambiri za tochi ndi liwiro la kuyenda ngakhale pamalo ozungulira.

2.2 Kuwotcherera kwa Laser kwa Zigawo Zopanda Mipanda

Mapaipi amakono otulutsa mpweya nthawi zambiri amakhala ndi mipanda yopyapyala kuti achepetse kulemera kwinaku akusunga mphamvu. Maloboti owotcherera a laser, okhala ndi mphamvu zambiri komanso ma weld seams ocheperako, amalepheretsa kugonja ndikusunga zinthu zakuthupi. Izi ndizopindulitsa makamaka pamakina otulutsa zitsulo zosapanga dzimbiri, pomwe kulondola ndikofunikira.

2.3 Kuwotcherera kwa Multi-Pass kwa Zolumikizana Zokhuthala

Kwa makina otulutsa mpweya wolemetsa m'magalimoto amalonda, makina a robotic gas metal arc welding (GMAW) amagwiritsa ntchito ma welds angapo kuti apange zolumikizana zolimba pakati pa mapaipi okhala ndi mipanda yokhuthala ndi mabulaketi. Adaptive welding algorithms amasintha magawo munthawi yeniyeni kuti athe kutengera kusiyanasiyana kwazinthu.

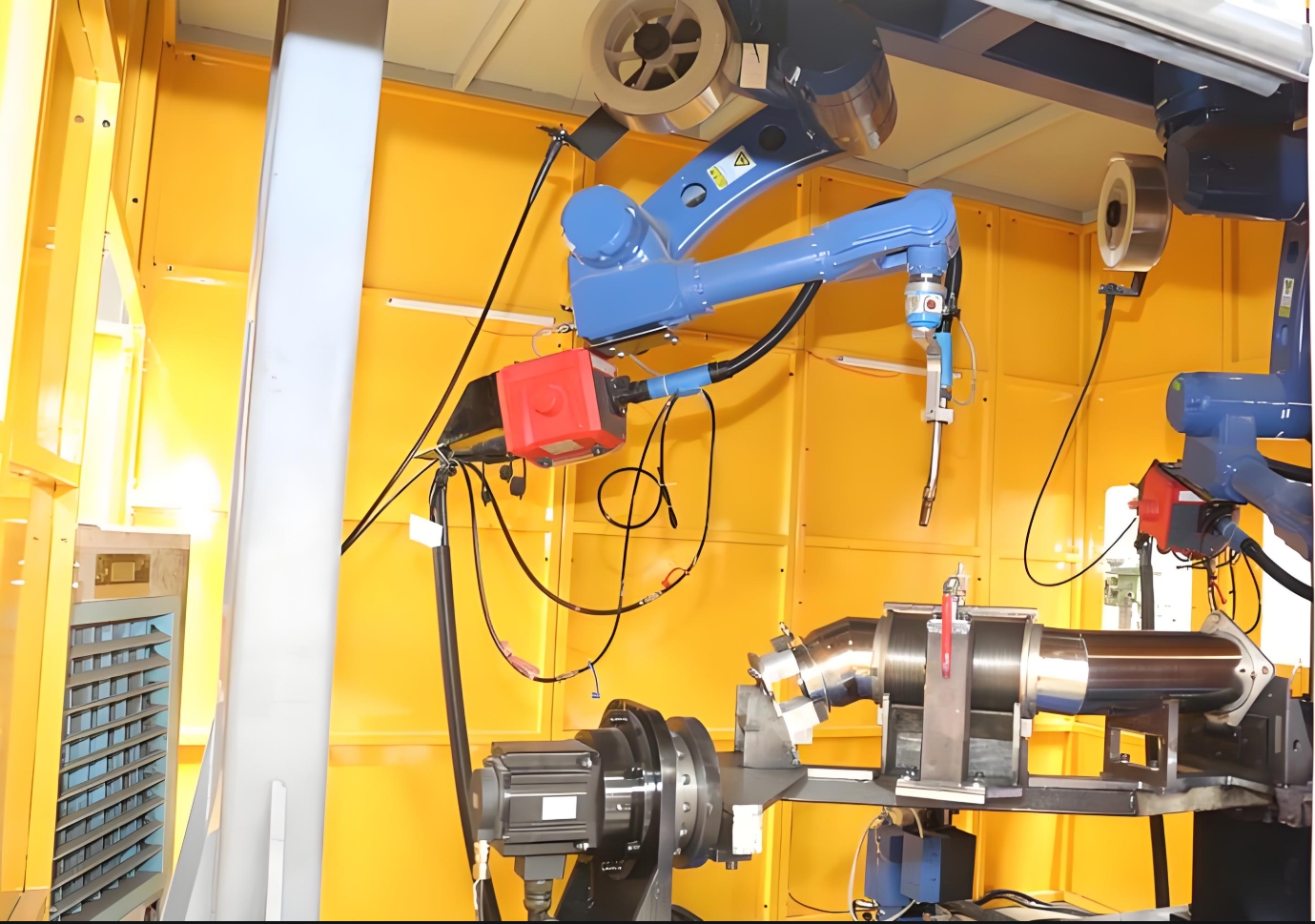

3. Kupititsa patsogolo Kusinthasintha ndi Rotary Tilt Positioners

Kugwira ntchito bwino kwa selo yowotchera maloboti kumadalira kulumikizana kosasinthika pakati pa loboti ndi chogwirira ntchito.Ma rotary tilt positionersndi zofunika kwambiri pa ntchitoyi, zomwe zimathandiza kuti ma degree 360 azizungulira komanso kupendekeka kwa mapaipi otulutsa mpweya panthawi yowotcherera. Ubwino umaphatikizapo:

- Mulingo woyenera Joint Kufikika: Woyimilira amawongoleranso chitoliro kuti awonetse seam yowotcherera pamalo athyathyathya kapena opingasa, kupangitsa kuti loboti ikhale yosavuta komanso kuchepetsa nthawi yozungulira.

- Kuchepetsa Kuyikanso: Mwa kusintha mwamphamvu chogwirira ntchito, loboti imatha kumaliza ma welds angapo pakakhazikitsidwe kamodzi, kuchepetsa nthawi yopanda ntchito.

- Kupititsa patsogolo Ergonomics: Othandizira amanyamula / kutsitsa zida pomwe loboti imawotcherera, kukulitsa kutulutsa.

Mwachitsanzo, choyimira chapawiri chimalola chitoliro chimodzi kuwotcherera pomwe chotsatiracho chimayikidwa, kukwanitsa kupanga pafupifupi mosalekeza.

4. Kukonzekera Mwachindunji: Msana Wakugwirizanitsa

Zosinthidwa mwamakondazida kuwotchererandizofunika kwambiri kuti mugwiritsire ntchito zida zotulutsa mpweya molumikizana ndendende ndi kuwotcherera kwa robotic. Zolinga zazikulu zamapangidwe ndizo:

- Njira Zothirira: Pneumatic kapena hydraulic clamps amateteza mapaipi, flanges, ndi mabatani popanda kuwononga malo.

- Modularity: Zosintha mwachangu zimatengera ma diameter osiyanasiyana kapena masinthidwe, oyenera kupanga mitundu yosakanikirana.

- Thermal Management: Zokonza zopangidwa kuchokera kuzinthu zosagwira kutentha zimapirira kutetezedwa kwa nthawi yayitali ndi ma welding arcs.

Zosintha zapamwamba zimaphatikiza masensa kuti atsimikizire kuyika kwa chigawocho musanayambe kuwotcherera, ndikuchotsa zolakwika zomwe zasokonekera.

5. Kuwerengera Mwachangu Kupindula

Kukhazikitsidwa kwa makina owotcherera ma robotiki pakupanga mapaipi otulutsa mpweya kumabweretsa kusintha koyezeka:

- Kuchepetsa Nthawi Yozungulira: Wowotcherera wa robotic MIG amatha kumaliza kuwotcherera mozungulira mumasekondi 60, poyerekeza ndi masekondi 180+ pakuwotcherera pamanja.

- Nthawi Yapamwamba: Maloboti amagwira ntchito 24/7 ndi kutsika kochepa, kukulitsa kutulutsa kwapachaka ndi 30-50%.

- Kusunga Zinthu Zofunika: Kuwongolera moyenera kwa parameter kumachepetsa spatter ndi kukonzanso, kutsitsa mtengo wogula ndi 15-20%.

Mwachitsanzo, wogulitsa magalimoto a Tier-1 adanenanso aKuwonjezeka kwa 40% pazowonjezerapambuyo potumiza ma cell a robotic okhala ndi ma synchronized positioners kuti azitha kutulutsa mpweya.

6. Kukweza Ubwino ku Miyezo ya Magalimoto

Kuwotcherera kwa roboti kumatsimikizira kutsata ma benchmark amagalimoto monga IATF 16949:

- Kubwerezabwereza: Maloboti amabwereza njira zowotcherera ndi ± 0.1 mm kulondola, kuchotsa kusinthasintha kwa anthu.

- Kuzindikira Chilema: Machitidwe ophatikizika a masomphenya kapena masensa oyang'anira ma arc amazindikira zolakwika zapakatikati, zomwe zimayambitsa kuwongolera mwachangu.

- Zolemba: Makina opanga makina amapanga zipika zowotcherera, zofunikira pakuwunika ndi kukumbukira.

Kuyang'ana pambuyo pa weld kumawonetsa kuti makina a robotic amachepetsa porosity ndi ming'alu ndi 90% poyerekeza ndi njira zamabuku.

7. Kukhazikika ndi Zochitika Zamtsogolo

Opanga magalimoto akuika patsogolo kukhazikika. Kuwotcherera kwa Robotic kumathandizira kusinthaku ndi:

- Kuchepetsa Kugwiritsa Ntchito Mphamvu: Kugwiritsa ntchito bwino kwa arc-on nthawi komanso njira zoyenda bwino zimachepetsa kugwiritsa ntchito mphamvu.

- Kuchepetsa Zinyalala: Kuchuluka kwa zokolola zoyambirira kumachepetsa zotsalira.

- Kuthandizira Lightweighting: Kuwotcherera kolondola kumathandizira kugwiritsa ntchito zida zapamwamba, zoonda popanda kusokoneza kulimba.

Kuyang'ana kutsogolo,Maloboti owotcherera oyendetsedwa ndi AIidzathandizira kuphunzira kwamakina kuti muzitha kudzikonza nokha magawo azinthu zatsopano, pomwemaloboti ogwirizana (cobots)idzathandiza ogwira ntchito kupanga magulu ang'onoang'ono.

Mapeto

M'malo otsogola kwambiri opanga makina otulutsa utsi wamagalimoto, maloboti owotcherera - ophatikizidwa ndi oyika anzeru ndi zida zake - amayimira ukadaulo wapamwamba kwambiri. Pogwiritsa ntchito makina ovuta kuwotcherera, makinawa amapatsa mphamvu opanga kuti akwaniritse nthawi yozungulira mwachangu, mawonekedwe abwino, komanso kupanga scalable. Pamene malamulo otulutsa utsi akukulirakulira komanso mapangidwe agalimoto akusintha, ukadaulo wowotcherera wa robotic ukhalabe mwala wapangodya waukadaulo, kuyendetsa bizinesi yamagalimoto kukhala tsogolo labwino komanso loyera.

Kwa opanga maloboti a mafakitale, kugogomezera kuthekera kumeneku pakugwiritsa ntchito mapaipi opopera sikungowonetsa ukatswiri waukadaulo komanso kuyika mayankho awo ngati othandizana nawo pakupititsa patsogolo luso lopanga magalimoto.

Nthawi yotumiza: Mar-21-2025