Choyamba, njira yowombera gasi yoteteza

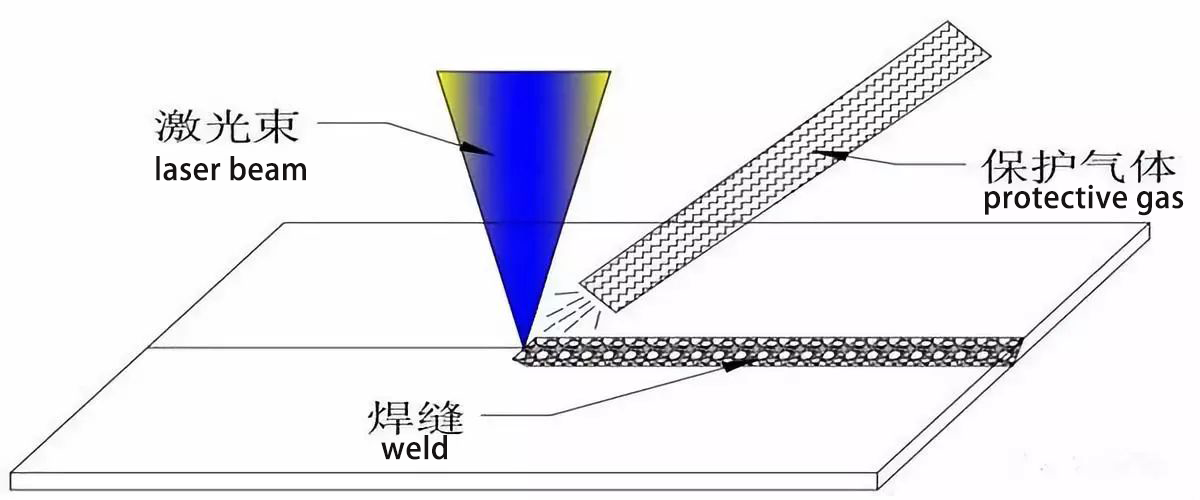

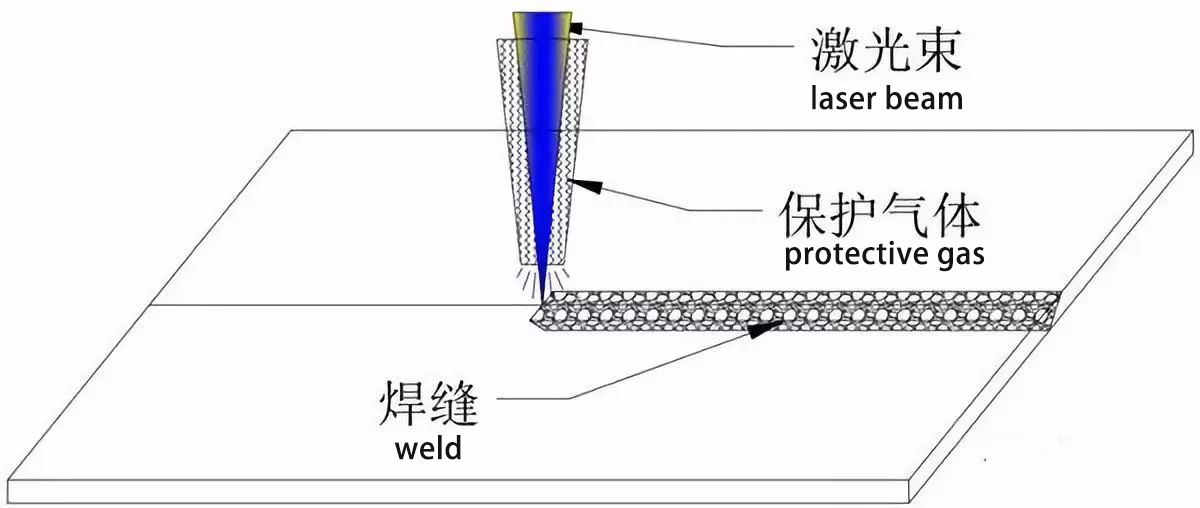

Pakalipano, pali njira ziwiri zazikulu zowomba mpweya wotetezera: imodzi ndi mpweya wotetezera mbali ya paraxial, monga momwe tawonetsera pa Chithunzi 1; Wina ndi mpweya woteteza coaxial.Kusankha kwapadera kwa njira ziwiri zowomba kumaganiziridwa m'zinthu zambiri. Nthawi zambiri, tikulimbikitsidwa kugwiritsa ntchito kuwomba mbali kuteteza mpweya

paraxial kuwomba gasi chitetezo

coaxial kuwomba gasi chitetezo

coaxial kuwomba gasi chitetezoAwiri, chitetezo gasi kuwomba mode kusankha mfundo

Choyamba, ziyenera kuonekeratu kuti zomwe zimatchedwa weld ndi "oxidized" ndi dzina lodziwika bwino. Mwachidziwitso, amatanthauza kachitidwe ka mankhwala pakati pa weld ndi zinthu zovulaza mumlengalenga, zomwe zimabweretsa kuwonongeka kwa ubwino wa weld. Ndizofala kuti zitsulo zowotcherera zimachita ndi mpweya, nayitrogeni ndi haidrojeni mumlengalenga pa kutentha kwina.

Kuletsa weld kukhala "oxidized" ndiko kuchepetsa kapena kupewa kukhudzana ndi zinthu zovulaza zotere ndi chitsulo chowotcherera pa kutentha kwakukulu. Kutentha kwapamwamba kumeneku sikuli kokha chitsulo chosungunuka cha dziwe, koma nthawi yonseyi kuyambira nthawi yomwe zitsulo zowotcherera zimasungunuka mpaka kulimba kwa chitsulo cha dziwe ndi kutentha kwake kumachepetsedwa ndi kutentha kwina pansi.

Chachitatu, potengera chitsanzo.

Mwachitsanzo, titaniyamu aloyi kuwotcherera, pamene kutentha ndi pamwamba 300 ℃ akhoza mwamsanga kuyamwa haidrojeni, oposa 450 ℃ akhoza mwamsanga kuyamwa mpweya, oposa 600 ℃ akhoza msanga kuyamwa nayitrogeni, kotero titaniyamu aloyi kuwotcherera msoko pambuyo solidification ndi kuchepetsa kutentha kwa 300 ℃ pansipa siteji ayenera kukhala ogwira chitetezo, apo ayi, izo zidzakhala zogwira mtima chitetezo.

Kuchokera kufotokozedwa pamwambapa sikovuta kumvetsa, chitetezo cha mpweya kuwomba osati pa nthawi yake kuteteza weld wosungunula dziwe, komanso ayenera kukhala welded malo ozizira chitetezo, kotero ambiri kutengera paraxial anasonyeza mu chithunzi 1 mbali mpweya woteteza, chifukwa njira imeneyi ndi njira zotetezera chitetezo cha njira ya coaxial chitetezo cha chiwerengero 2.

Mbali ya paraxial ikuwomba pamakina opangira uinjiniya, sizinthu zonse zomwe zingagwiritse ntchito njira yodzitchinjiriza kumbali ya shaft, pazinthu zina zenizeni, zitha kugwiritsa ntchito mpweya woteteza coaxial, zosowa zenizeni kuchokera pamapangidwe azinthu ndi kusankha kolumikizana kolumikizana.

Chachinayi, kusankha njira yodzitetezera yomwe ikuwomba gasi

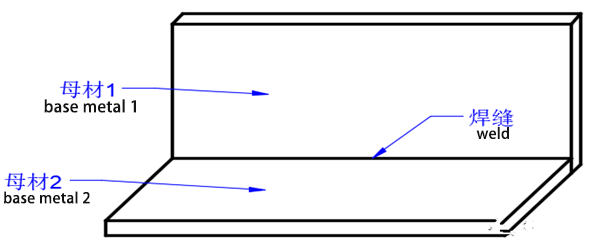

1. Zowotcherera molunjika

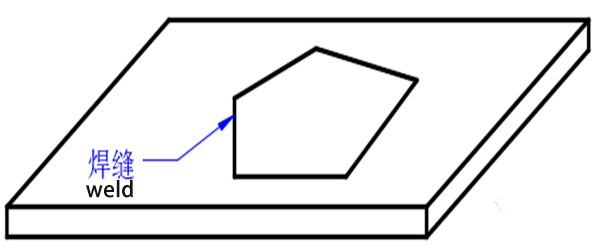

Monga momwe chithunzi 3 chikuwonetsedwera, mawonekedwe a weld a chinthucho ndi mzere wowongoka, ndipo mawonekedwe olumikizana amatha kukhala olowa m'matako, olowa m'chiuno, pakona yolakwika kapena kuwotcherera. Pazinthu zamtunduwu, ndikwabwino kutengera njira yakumbali yowuzira mpweya wodzitetezera monga momwe tawonera pachithunzi 1.

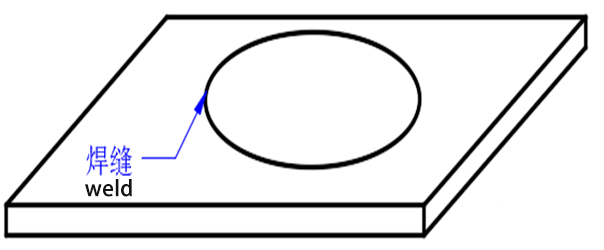

2. Lathyathyathya chatsekedwa chithunzi weld

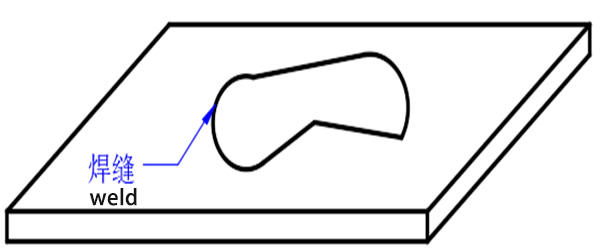

Monga momwe tawonetsera pa Chithunzi 4, mawonekedwe owotcherera a mankhwalawa ndi mawonekedwe ozungulira ndege, mawonekedwe amitundu yambiri, mawonekedwe a mzere wamitundu yambiri ndi mawonekedwe ena otsekedwa. Mawonekedwe olowa akhoza kukhala olowa m'chiuno, olowa m'chiuno, kuwotcherera kolowera ndi zina zotero. Pazogulitsa zamtunduwu, ndikwabwino kutengera njira yodzitetezera ya coaxial yomwe ikuwonetsedwa pazithunzi 2.

Kusankhidwa kwa mpweya wodzitetezera kumakhudza kwambiri khalidwe la kuwotcherera, mphamvu ndi mtengo wa kupanga, koma chifukwa cha kusiyana kwa zinthu zowotcherera, mu ndondomeko yeniyeni yowotcherera, kusankha kwa mpweya wowotcherera kumakhala kovuta kwambiri, kumafunika kuganizira mozama za zinthu zowotcherera, njira yowotcherera, malo owotcherera, komanso zofunikira za kuwotcherera, kupyolera mu mayesero owotcherera kuti asankhe zotsatira zoyenera kuwotcherera kuti akwaniritse bwino.

Gwero: Welding Technology

Nthawi yotumiza: Sep-02-2021