Bingo TIG makina owotcherera

Tioneni Tikugwira Ntchito!

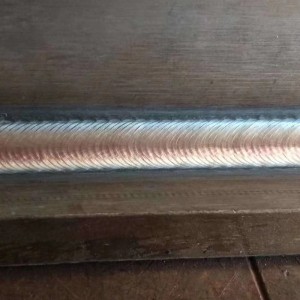

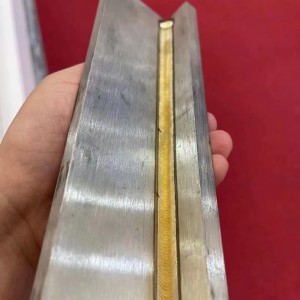

Chitsanzo Chodziwika Chotsatira

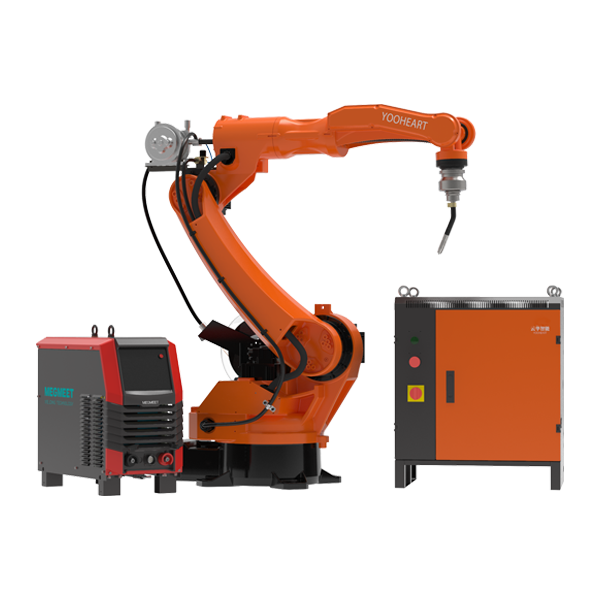

TIG kuwotcherera Mphamvu Gwero, Buku & Robot chitsanzo, Kuthandizira zosiyanasiyana kulankhulana protocal

WSME 315/400/500/630

Makina owotcherera a AC ndi DC pulse argon arc

Ntchito:

AC nthawi zonse TIG, AC pulse TIG, DC nthawi zonse TIG, AC pulse TIG, manual mental-arc kuwotcherera.

Makampani ogwiritsira ntchito:

Azamlengalenga, gawo la mlengalenga, mafakitale a petrochemical, chosinthira kutentha, mipando ya aluminiyamu ndi kuwala kwa njinga.

Mawonekedwe:

Opaleshoni gulu ndi masanjidwe wololera, ntchito wolemera ndi ntchito yabwino;

◆ The kuwotcherera parameter akhoza preset ndendende;

◆ Mafupipafupi a AC ndi kuyeretsa m'lifupi akhoza kusinthidwa payekha kuti akwaniritse zosowa za ndondomeko yowotcherera pazinthu zosiyanasiyana za aluminiyamu;

◆ Ili ndi kugunda kosavuta kwa arc, khola lamagetsi lokhazikika komanso dziwe lowotcherera losavuta;

◆ Kuwotcherera kwa argon kungathe kuteteza mfuti yowotcherera kuti isawonongeke;

◆ Kuwotcherera pakali pano kungawongoleredwe patali;

◆ Kulowetsa kwa weld ndi m'lifupi mwake komwe kumafunidwa ndi cholumikizira chowotcherera ndi kuchuluka kwa mawonekedwe a waveform kutha kupezedwa mwa kusintha kwa pulse pakali pano, pafupipafupi, pafupipafupi, kuchuluka kwantchito, kusinthasintha kwapano, ma frequency a AC, kuyeretsa gawo ndi chiŵerengero cha AC kukondera pamene AC argon kuwotcherera kwa arc kumagwiritsidwa ntchito kutalikitsa moyo wautumiki, makamaka pa kuwotcherera basi ndi kuwotcherera kwa loboti.

| Chitsanzo | WSME- -315R | WSME-400 | Mtengo wa WSME-500 | WSME-630 |

| Adavotera voteji / pafupipafupi | Magawo atatu380V (+/-) 10% 50Hz | |||

| Adavotera mphamvu (KVA) | 12.1 | 17.1 | 25.7 | 34.7 |

| Zovotera panopa (A) | 18.5 | 26 | 39 | 53 |

| Muyezo wokhazikika wa katundu (%) | 60 | 60 | 60 | 60 |

| Mphamvu yamagetsi yamagetsi osatulutsa (V) | 63 | 70 | 79 | 79 |

| Mtundu wapano (A) | 5-315 | 5-400 | 20-500 | 20-630 |

| Arc kuyambira pano (A) | 10-315 | 10-400 | 20-500 | 20-630 |

| Peak current (A) | 5-315 | 10-400 | 20-500 | 20-630 |

| Arc kuyimitsa pano (A) | 5-315 | 10-400 | 20-500 | 20-630 |

| Nthawi yoyambira (S) | 0.1-15 | |||

| Nthawi yoyimitsa gasi (S) | 0.1-20 | |||

| Kuthamanga kwafupipafupi (Hz) | 0.2-20 | |||

| Pulse duty (%) | 1-100% | |||

| AC pafupipafupi (Hz) | 20-200 | 20-200 | 20-100 | 20-100 |

| TIG woyendetsa arc kalembedwe | Mtengo wa HF | |||

| Mphamvu yamakono (A) | 30-315 | 50-400 | 50-500 | 50-630 |

| Kuziziritsa mode | Kuziziritsa madzi | |||

| Insulation kalasi | H/B | |||

WSM 315/400/500

Makina owotcherera a DC pulse argon arc

Ntchito:

DC nthawi zonse TIG, DC kugunda TIG, manual metal-arc kuwotcherera.

Makampani ogwiritsira ntchito:

Makampani a petrochemical, chotengera chopondereza, kumanga mphamvu zamagetsi, chombo, njinga, mphamvu ya nyukiliya ndi kuyala mapaipi.

Mawonekedwe:

◆ The gulu ntchito ndi masanjidwe wololera, ntchito wolemera ndi ntchito yabwino;

◆Parameters monga kukwera pang'onopang'ono ndi kutsika pang'onopang'ono kwa magetsi, mafupipafupi, chiwerengero cha ntchito, nthawi ya mpweya wopita patsogolo ndi mpweya wotsalira akhoza kukhazikitsidwa bwino;

◆ The manual metal-arc kuwotcherera amatha kusintha mphamvu ya magetsi ya arc kukantha ndi kukankhira, ndi kugunda kosavuta kwa arc ndikuletsa kumamatira kwa ndodo yowotcherera;

◆ Kuwotcherera kwa argon kungathe kuteteza mfuti yowotcherera kuti isawonongeke;

◆ Ili ndi magawo awiri ndi njira zinayi zowongolera kuwotcherera;

◆Ndi yaying'ono komanso yopepuka komanso yosavuta kuyenda;

◆Pakali pano ndi magetsi amatha kuwonetsedwa nthawi imodzi.The kuwotcherera panopa akhoza preset ndendende;

◆TIG imatha kusankha njira yonyamulira pafupipafupi kugunda kwa arc.

| Chitsanzo | WSM-315 | WSM-400 | Mtengo wa WSM-500 | ||

| Ma voliyumu olowera / pafupipafupi | Gawo lachitatu380V(+/-)10% 50Hz | ||||

| Adavotera mphamvu (KVA) | 11.2 | 17.1 | 23.7 | ||

| Zovotera panopa (A) | 17 | 26 | 36 | ||

| Muyezo wokhazikika wa katundu (%) | 60 | 60 | 60 | ||

| DC nthawi zonse Welding panopa (A) | 5-315 | 5-400 | 5-500 | ||

| DC pulse | Peak current (A) | 5-315 | 5-400 | 5-500 | |

| Base current (A) | 5-315 | 5-400 | 5-500 | ||

| Pulse duty (%) | 1-100 | ||||

| Kuthamanga kwafupipafupi (Hz) | 0.2-20 | ||||

| TIG | Arc kuyambira pano (A) | 10-160 | |||

| Arc kuyimitsa pano (A) | 5-315 | 5-400 | 5-500 | ||

| Nthawi yoyambira (S) | 0.1-15 | ||||

| Nthawi yotsalira ya gasi- -kuyimitsa (S) | 0.1-20 | ||||

| TIG woyendetsa arc kalembedwe | Mtengo wa HF | ||||

| Kuwotcherera kwa arc pamanja (A) | 30-315 | 40-400 | 50-500 | ||

| Kuziziritsa mode | Madzi ozizira / Air kuzirala | ||||

| Gawo lachitetezo cha zipolopolo | IP21S | ||||

| Insulation kalasi | H/B | ||||

WSM -S/YS 400

Makina owotcherera a DC pulse argon arc

| Chitsanzo | WSM-400S/YS | ||

| Ma voliyumu olowera / pafupipafupi | Gawo lachitatu380V(+/-)10% 50Hz | ||

| Adavotera mphamvu (KVA) | 17.1 | ||

| Zovotera panopa (A) | 26 | ||

| Muyezo wokhazikika wa katundu (%) | 60 | ||

| DC nthawi zonse Welding panopa (A) | 5-400 | ||

| DC pulse | Peak current (A) | 5-400 | |

| Base current (A) | 5-400 | ||

| Pulse duty (%) | 1-100 | ||

| Kuthamanga kwafupipafupi (Hz) | 0.2-20 | ||

| Nthawi yoyambira (S) | 0.1-15 | ||

| Nthawi yotsalira ya gasi- -kuyimitsa (S) | 0.1-20 | ||

| Njira yogwirira ntchito ya arc stoping current | Masitepe awiri, Masitepe anayi | ||

| TIG woyendetsa arc kalembedwe | Mtengo wa HF | ||

| Kuziziritsa mode | Madzi ozizira / Air kuzirala | ||

| Gawo lachitetezo cha zipolopolo | IP21S | ||

| Insulation kalasi | H/B | ||

Ntchito:

DC nthawi zonse TIG, DC pulse TIG.

Makampani ogwiritsira ntchito:

Makampani a petrochemical, chotengera chopondereza, kumanga mphamvu zamagetsi, chombo, njinga, mphamvu ya nyukiliya ndi kuyala mapaipi.

Mawonekedwe:

◆ The gulu ntchito ndi masanjidwe wololera, ntchito wolemera ndi ntchito yabwino;

◆Parameters monga kukwera pang'onopang'ono ndi kutsika pang'onopang'ono kwa magetsi, mafupipafupi, chiwerengero cha ntchito, nthawi ya mpweya wopita patsogolo ndi mpweya wotsalira akhoza kukhazikitsidwa bwino;

◆ The manual metal-arc kuwotcherera amatha kusintha mphamvu ya magetsi ya arc kukantha ndi kukankhira, ndi kugunda kosavuta kwa arc ndikuletsa kumamatira kwa ndodo yowotcherera;

◆ Kuwotcherera kwa argon kungathe kuteteza mfuti yowotcherera kuti isawonongeke;

◆ Ili ndi magawo awiri ndi njira zinayi zowongolera kuwotcherera;Ndi yaying'ono komanso yopepuka komanso yabwino kuyenda;

◆Pakali pano ndi magetsi amatha kuwonetsedwa nthawi imodzi.The kuwotcherera panopa akhoza preset ndendende;

◆TIG amatha kusankha njira yonyamulira pafupipafupi ya arc;

◆ The anamanga-mu amphamvu waya chakudya dongosolo ali wolemera mindandanda yazakudya wa waya kudya, amene akhoza kukumana osiyana ndondomeko zofunika;

◆Mlingo wa chakudya cha mawaya ndi kugunda kwazomwe zikuchitika zokha.

Kulingalira kwa Welder

Pamene mbale ziwiri zachitsulo zokhala ndi makulidwe osiyanasiyana zimagwirizanitsidwa palimodzi, pofuna kupewa kupanikizika kwakukulu komwe kumachitika chifukwa cha kusintha kofulumira kwa gawo la mtanda, m'mphepete mwa mbale yowonjezereka nthawi zambiri imachepetsedwa pang'onopang'ono kuti mukwaniritse makulidwe omwewo pamphepete ziwiri.Kulimba kwa static ndi kutopa kwa mafupa a matako ndi apamwamba kuposa ziwalo zina.Pazolumikizira mosinthasintha, zonyamula katundu kapena kugwira ntchito m'ziwiya zotentha komanso zothamanga kwambiri, kuwotcherera mafupa am'matako nthawi zambiri kumakhala kokonda.Kukonzekera kwapang'onopang'ono kwa mgwirizano wa lap ndikosavuta, msonkhanowo ndi wosavuta, ndipo kuwotcherera ndi kupsinjika kotsalira kumakhala kochepa, kotero kumagwiritsidwa ntchito nthawi zambiri pakuyika mafupa ndi zida zosafunika pamalopo.Nthawi zambiri, ma lap joints sali oyenera kugwira ntchito pansi pamikhalidwe monga kusinthana katundu, media zowononga, kutentha kwambiri kapena kutsika.Kugwiritsa ntchito ma T-joints ndi zolumikizira zamakona nthawi zambiri zimachitika chifukwa cha zosowa zamapangidwe.Makhalidwe ogwirira ntchito a ma weld osakwanira a fillet pa T-joints ndi ofanana ndi ma welds a fillet pamiyendo.Pamene kuwotcherera ndi perpendicular kwa malangizo a kunja mphamvu, amakhala kutsogolo fillet kuwotcherera.Panthawiyi, mawonekedwe a weld pamwamba adzayambitsa magawo osiyanasiyana a kupsinjika maganizo;kupsinjika kwa kulowetsedwa kwa fillet weld ndikofanana ndi kuphatikizika kwa matako.

Chifukwa Chosankha ife

NDIFE AKULENGA

BINGOamafufuza mosalekeza ndikukulawanzeru kuwotcherera lusololani zida zambiri zowotchererakupita padziko lonse lapansi

NDIFE OCHITIKA

Tsopano izo zakhudzidwa ndi kuyanjidwandi mayiko ambirimtsogolomu

NDIFE OBWERA

Tiyika ndalama zambirimosalekeza r & d ndi kupangakupita patsogoloosasiya